CLIENT INFORMATION

The company sells trailers of all types, spare parts, as well as maintenance and repair of trailers. There are 2 stores in Moscow.

Bitrix24 employs 10 employees from different departments.

TASKS THE CLIENT CAME WITH

At the time of contacting us, the client had cloud Bitrix24. The following tasks had to be solved:

- Organize a system for assembling, shipping and delivering orders. The client has 2 stores, which are located in different parts of the city. When the sales department receives an order, it must first be prepared in the warehouse and assembled, if these are separate parts. Then, at the right time, send it to one of the stores for pickup or transfer it to drivers for targeted delivery. All communication between managers, warehouse workers, store salespeople and drivers was carried out via instant messengers, personal correspondence, and by phone. If something changed in the order, these issues were resolved in an emergency and chaotic manner, which created many problems for everyone.

Implement:

- Set up integration with 1C:UNF 3.0 and fix errors:

- Product synchronization did not work.

- The prices indicated in the Bitrix24 transaction were not transferred to 1C.

- VAT was calculated incorrectly.

- After editing the products in 1C, they did not change in Bitrix24.

IMPLEMENTATION PROCESS, PROJECT FEATURES

At the beginning of our work, we transferred the cloud portal to the boxed version of Bitrix24. This was necessary for further improvements.

Organization of assembly and delivery of orders

There are three departments involved here: sales, warehouse, logistics.

We called the head of the company and discussed the whole process and details. We compiled technical specifications for organizing schedules for assembly, shipment and delivery of orders. During the work process, intermediate calls were made to adjust the settings.

Then we carried out the implementation on the portal with integration into the existing sales funnel at a separate stage “For shipment”.

CRM

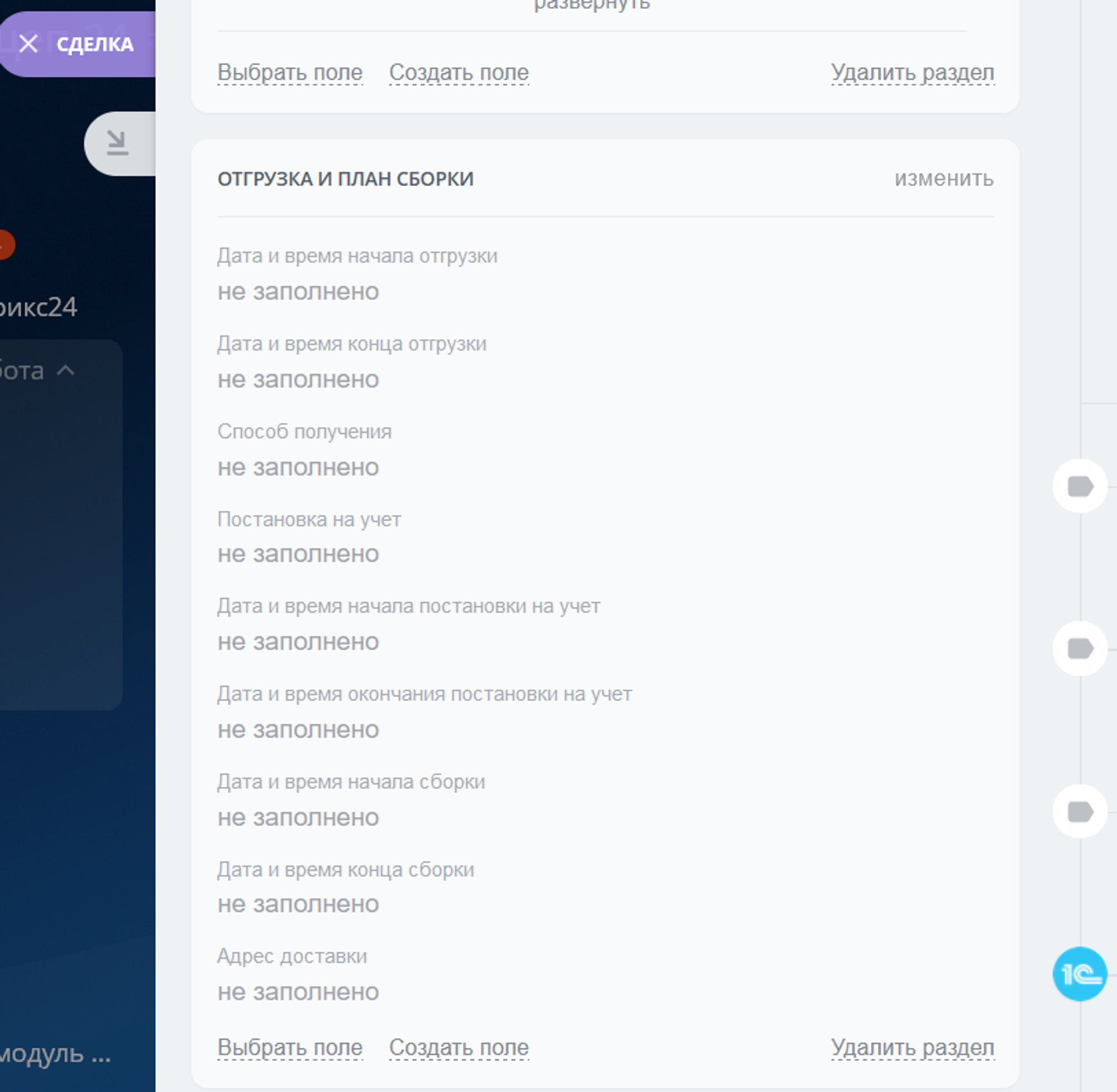

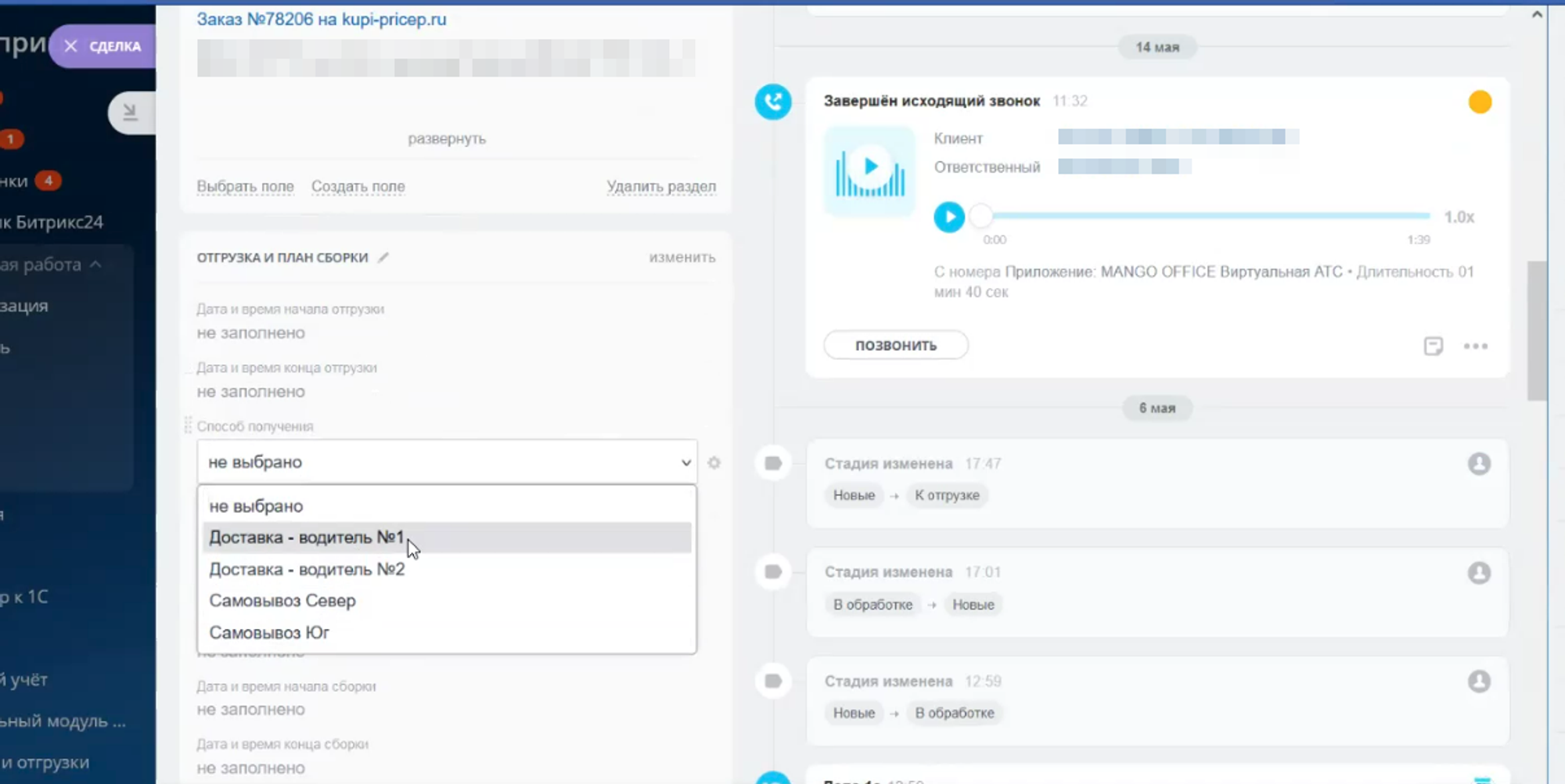

Created the corresponding fields in transactions

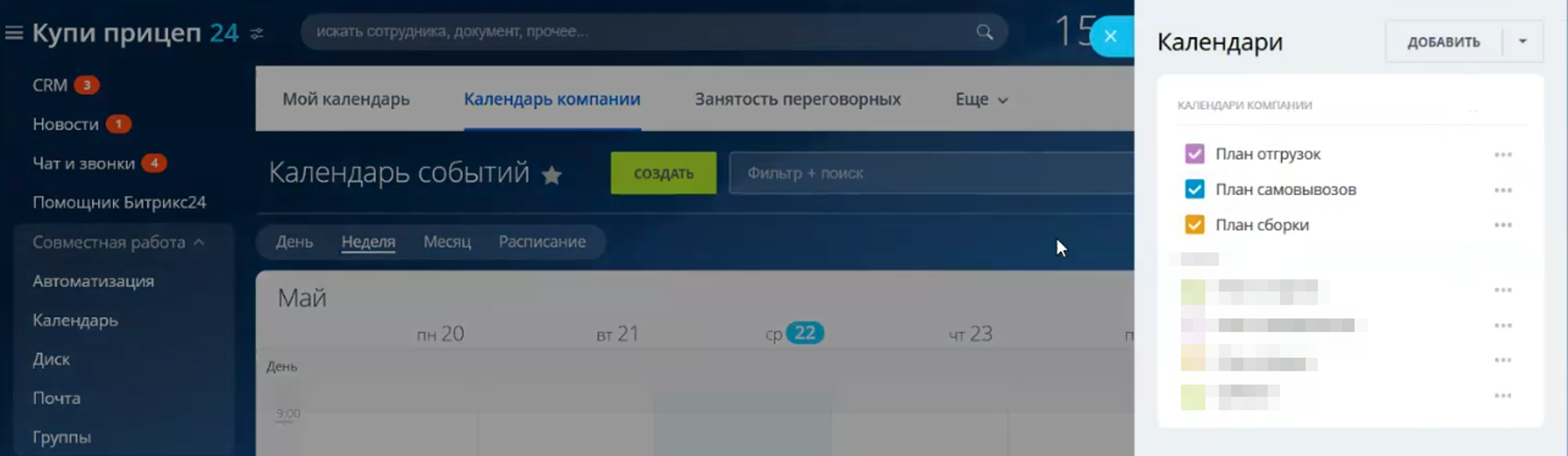

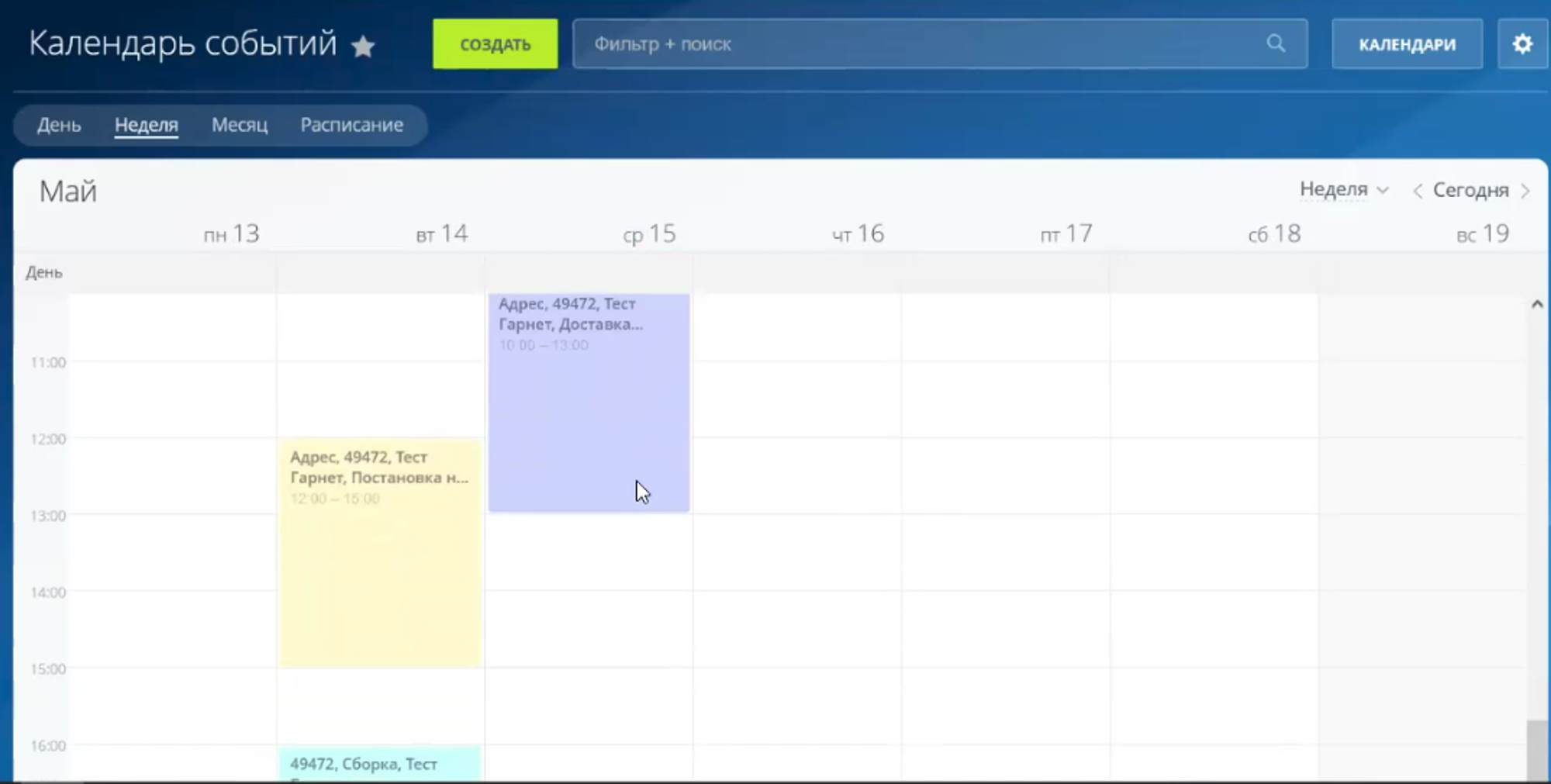

Next, we created three calendars: an assembly plan, a shipment plan, and a pickup plan.

They include tasks for warehouse employees, drivers and store salespeople, through which each of them sees their work plan.

The technical difficulty was in implementing different event colors for different drivers within one calendar (similarly with different stores, within a different calendar). The problem was solved by creating an event in the calendar through PHP code, where each parameter was set, including color.

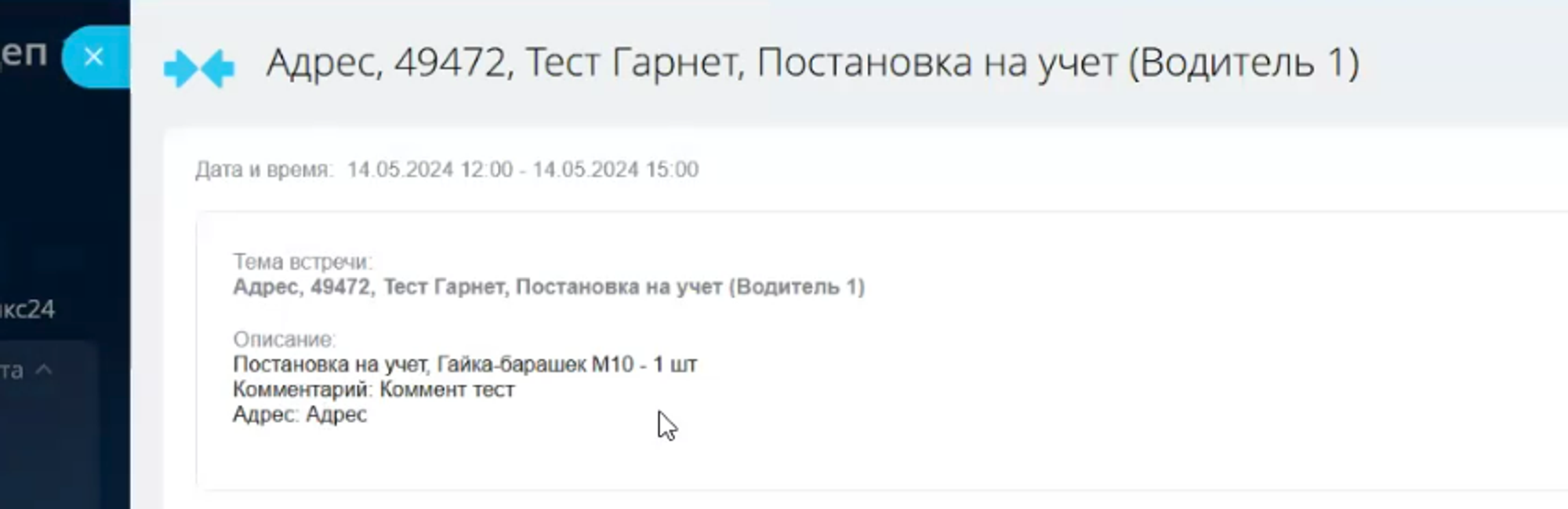

In a separate development, we formatted the contents of tasks and displayed additional information that was not included there by default, for example, the number of spare parts.

We also implemented a registration option. When the manager marks this parameter in the transaction, this information is added to the task for the driver who delivers the order.

Conducted a demonstration of the solution for the manager.

Business processes

We have set up the process of registering a trailer, which is displayed in the delivery schedule for drivers.

The process at the “For shipment” stage, which starts the entire cycle of organizing assembly, shipment and delivery of orders.

The process that is needed to clear all information in case something has changed in the order. He clears all fields, after which the manager enters the latest information.

Reports

We set up a report for the head of “Delivery and shipment”, it allows you to track what amounts were closed for each month. You can filter sales by a specific store; a filter by driver allows you to track how many hours each person spent on delivery.

1S

After switching to the boxed version of the portal, we transferred synchronization with 1C, which was previously on the cloud, adapted it and made additional settings.

Products are synchronized between Bitrix24 and 1C, any changes to them are immediately reflected in the systems, and prices from transactions in Bitrix24 immediately go to 1C.

WORKING WITH THE SOLUTION. RESULTS ACHIEVED

An order is received from the website and a deal is created. The manager communicates with the client regarding the order and fills out the following fields:

- Receipt method (pickup from the store/address delivery)

- Date and time of the start/end of shipment (information for warehouse workers when it is necessary to collect and transfer the order either to the store or to the driver)

Next comes automation. Based on the completed data, the system itself calculates the assembly time for a given order in the warehouse according to the given logic and assigns the appropriate task to the warehouse employee. For example, if delivery is scheduled for the morning, then assembly will take place the night before. Delivery tasks also appear for drivers and stores, respectively.

We have clearly described how the whole process works in this article. Order assembly and delivery schedule

BENEFITS FROM IMPLEMENTATION

We synchronized the work of 3 departments: sales, warehouse, logistics. The company now centrally automatically sets events for assembly, shipment and delivery.

Not a single order is lost. Each employee knows what he must do, when and at what time, thereby being responsible for completing his work. Information about orders and deliveries is not lost in emails or instant messengers; everything is in Bitrix24 and 1C. Each employee receives only that information on the order that relates to his direction.

The human factor is eliminated when assembling orders. When the manager specifies delivery, the system itself notifies the warehouse employee when the order needs to be prepared. And if there are any additions to it, the employees also see this and can quickly change the order.

The manager can easily schedule deliveries without fear that they will overlap at the same time. Since the system shows each driver’s schedule and free/occupied time slots.

All logistics are reliably built and there is no risk of delays or errors during order delivery.

All departments interact smoothly and effectively, and the manager has the ability to control all processes.