Автор статьи

Глеб Антоненко

For many companies, the issue of assembling orders for shipment at the warehouse, as well as organizing their delivery or pick-up, is a pressing issue.

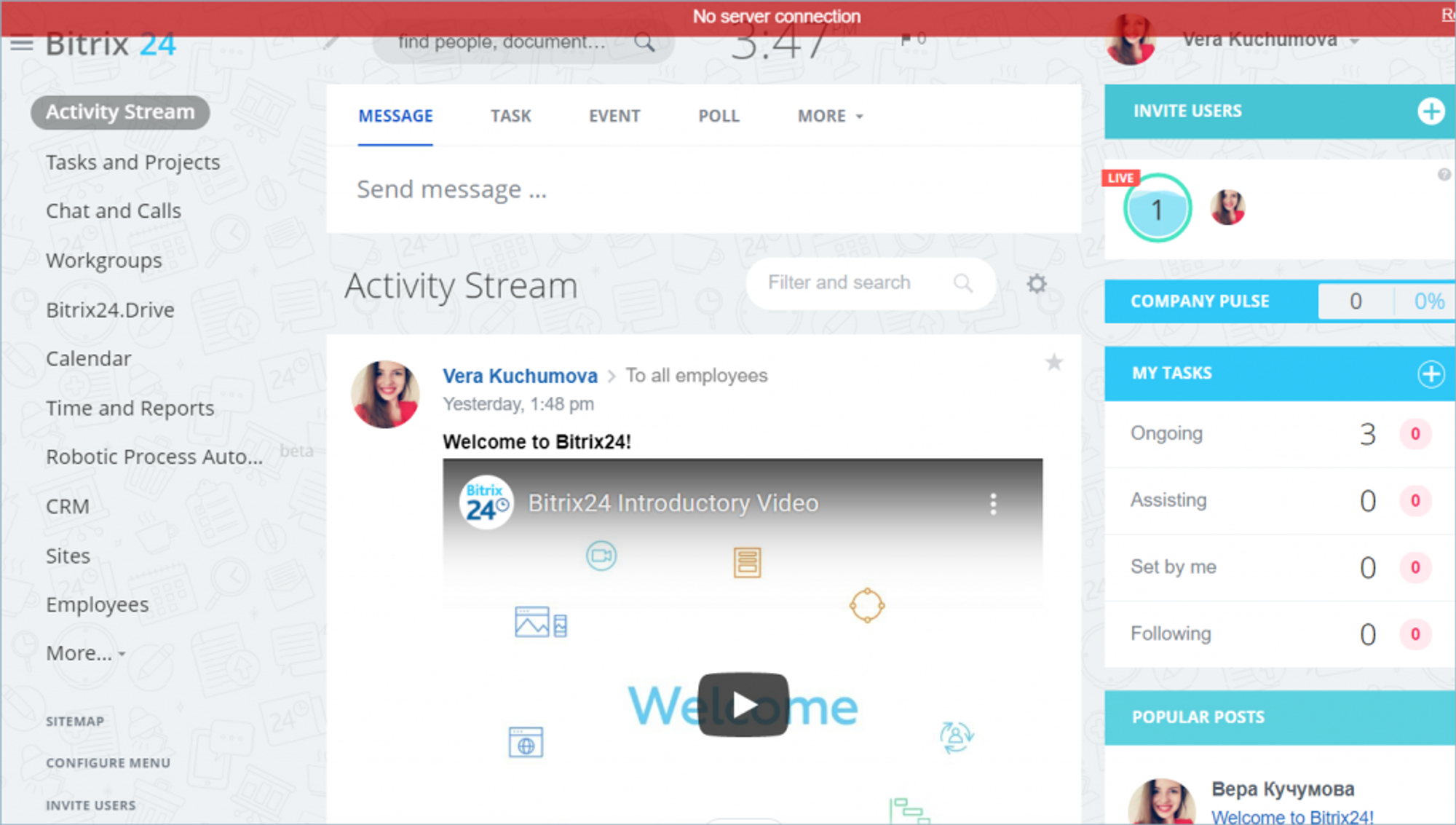

The Order Assembly and Delivery Schedule will help with this, which can be configured in the Bitrix24 calendar and synchronized with transactions.

With the help of such a schedule, it will be easy to track the status of order readiness; responsible employees in the warehouse and logistics will receive tasks with all information about the order, assembly dates, shipment and other information for delivery on time.

How does the Assembly and Delivery Schedule work?

Let's look at an example of an implemented case.

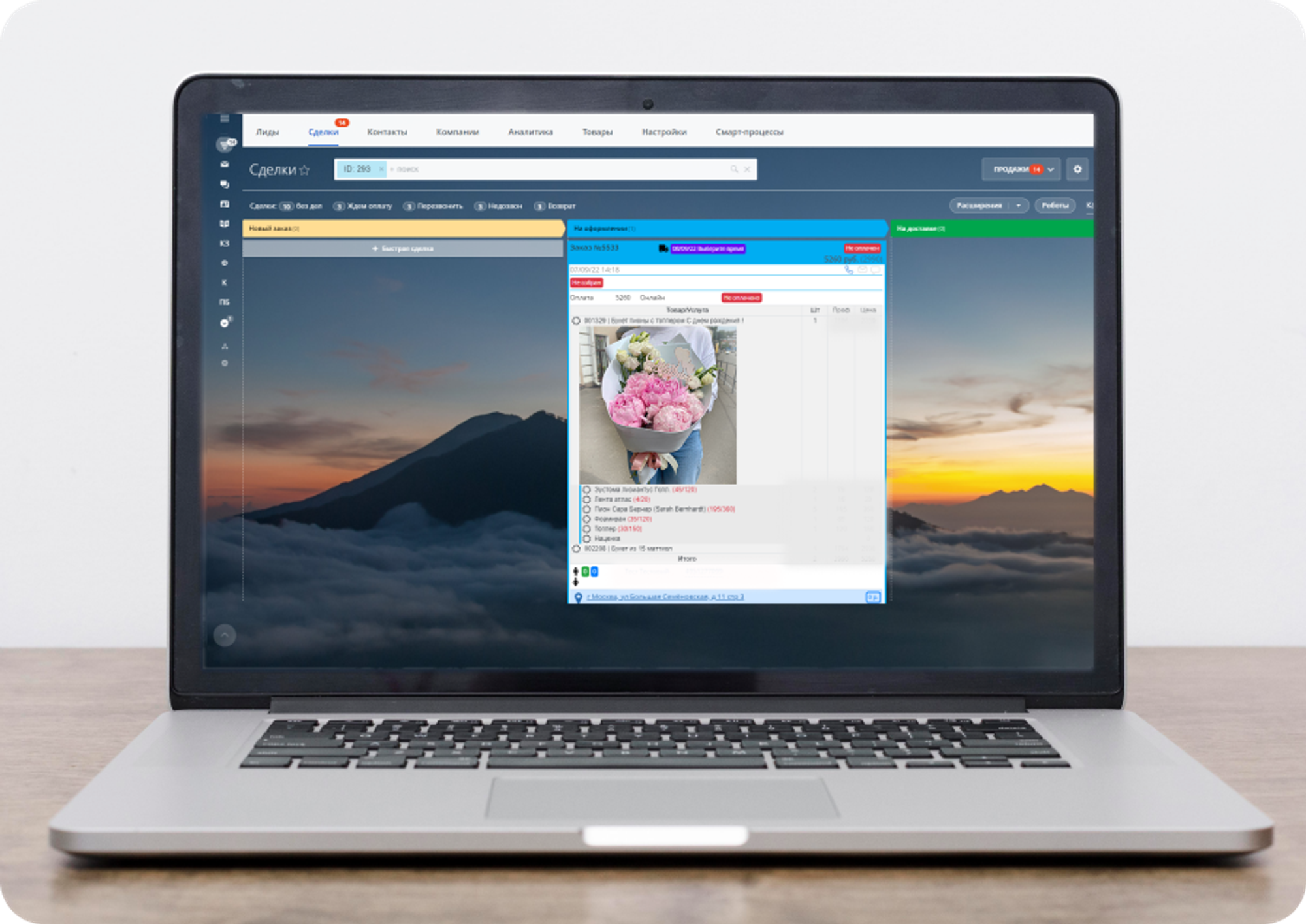

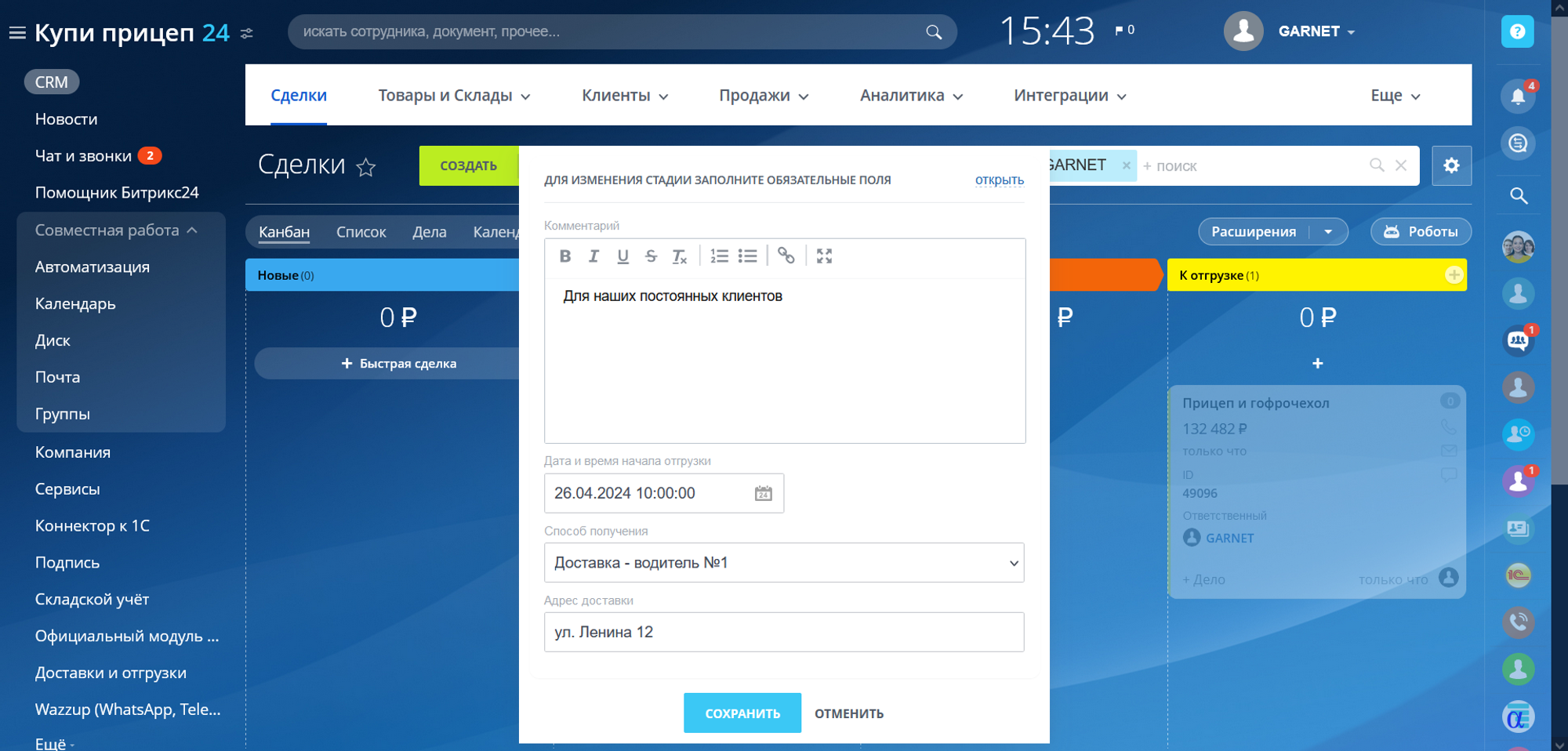

- When the order is completed, it moves to the “For shipment” stage. The manager receives a request to fill in information for assembly and delivery (if it was not previously specified). At the same time, in the “Delivery method” field there are different options, for example, pickup from the store or delivery by driver. There may be several stores and drivers in a company.

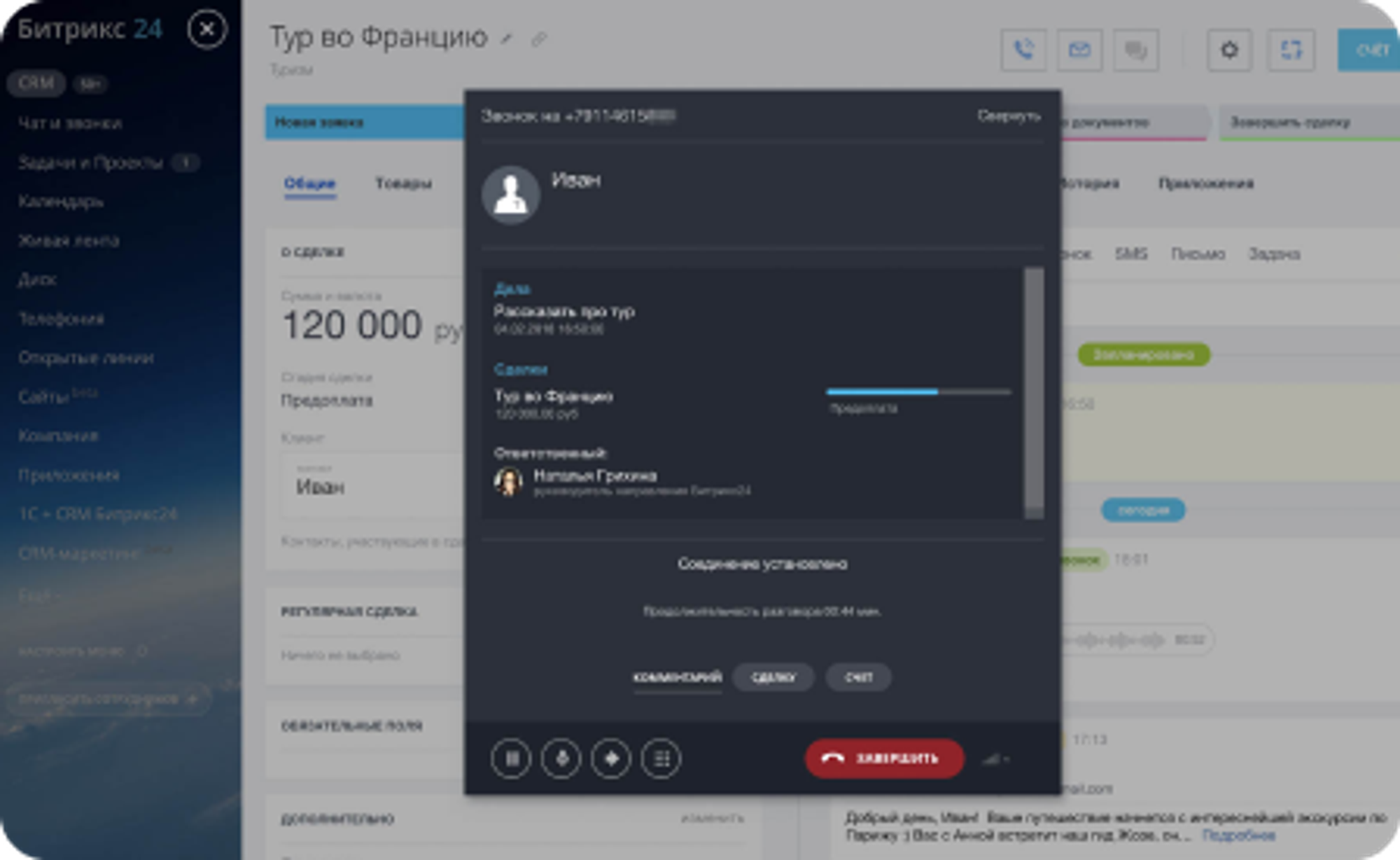

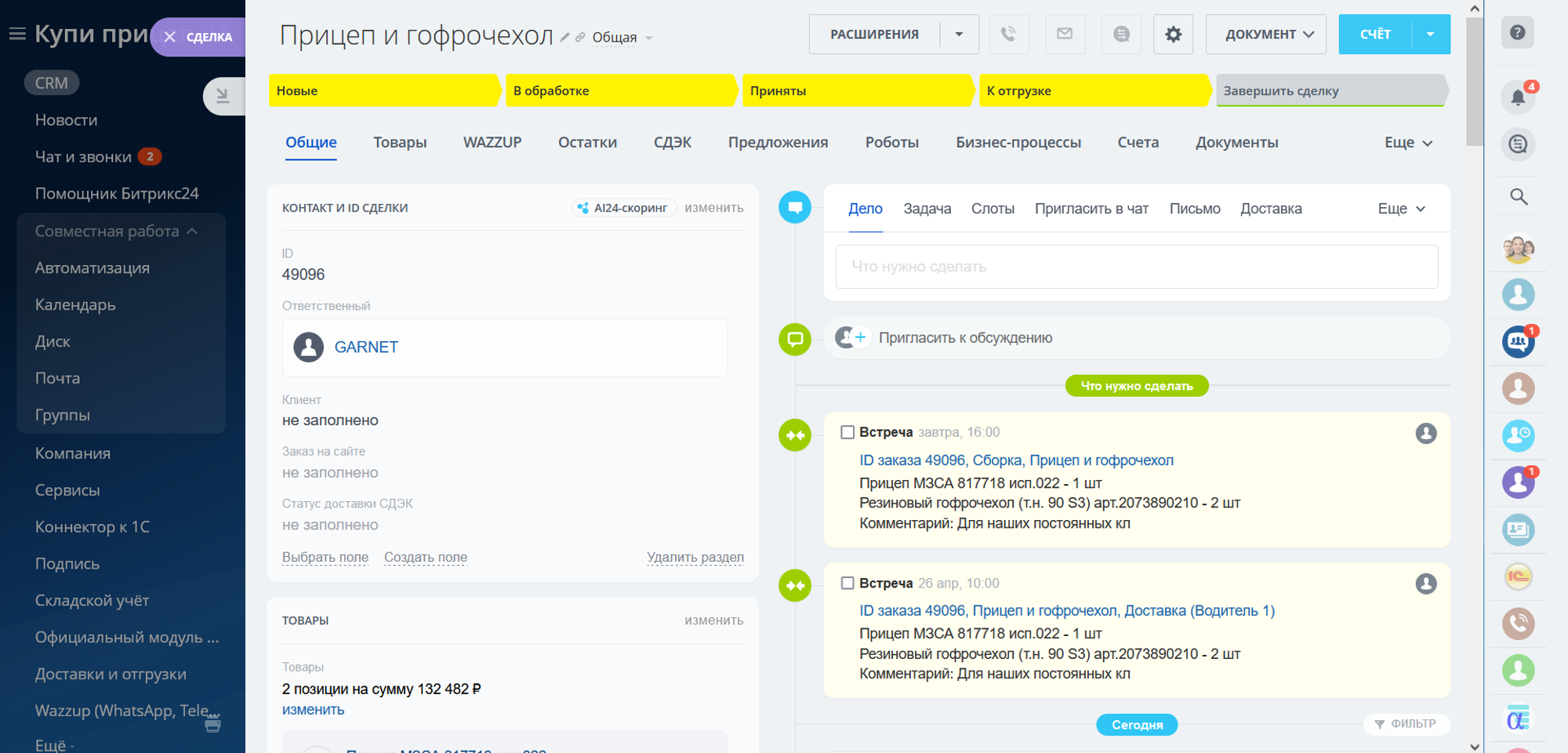

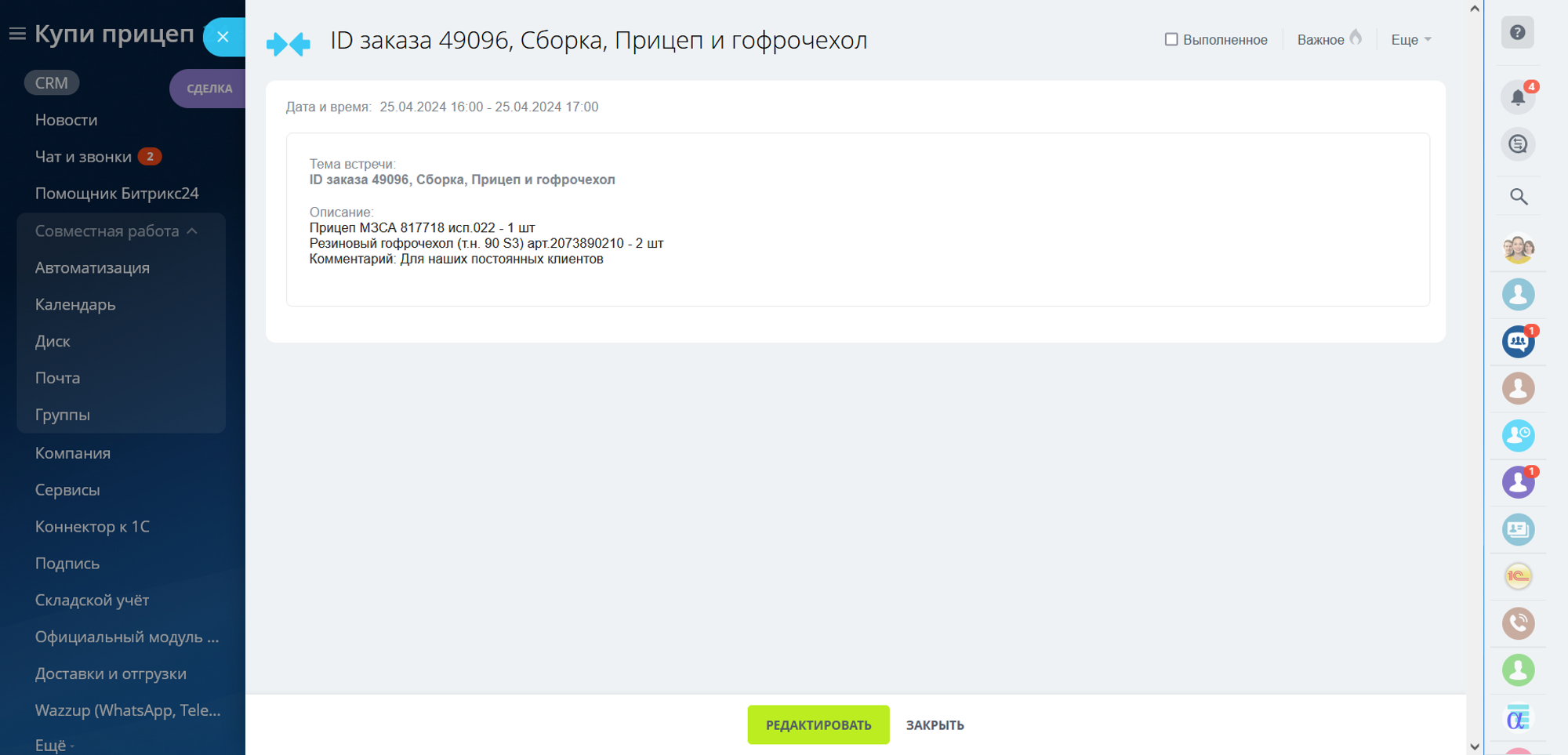

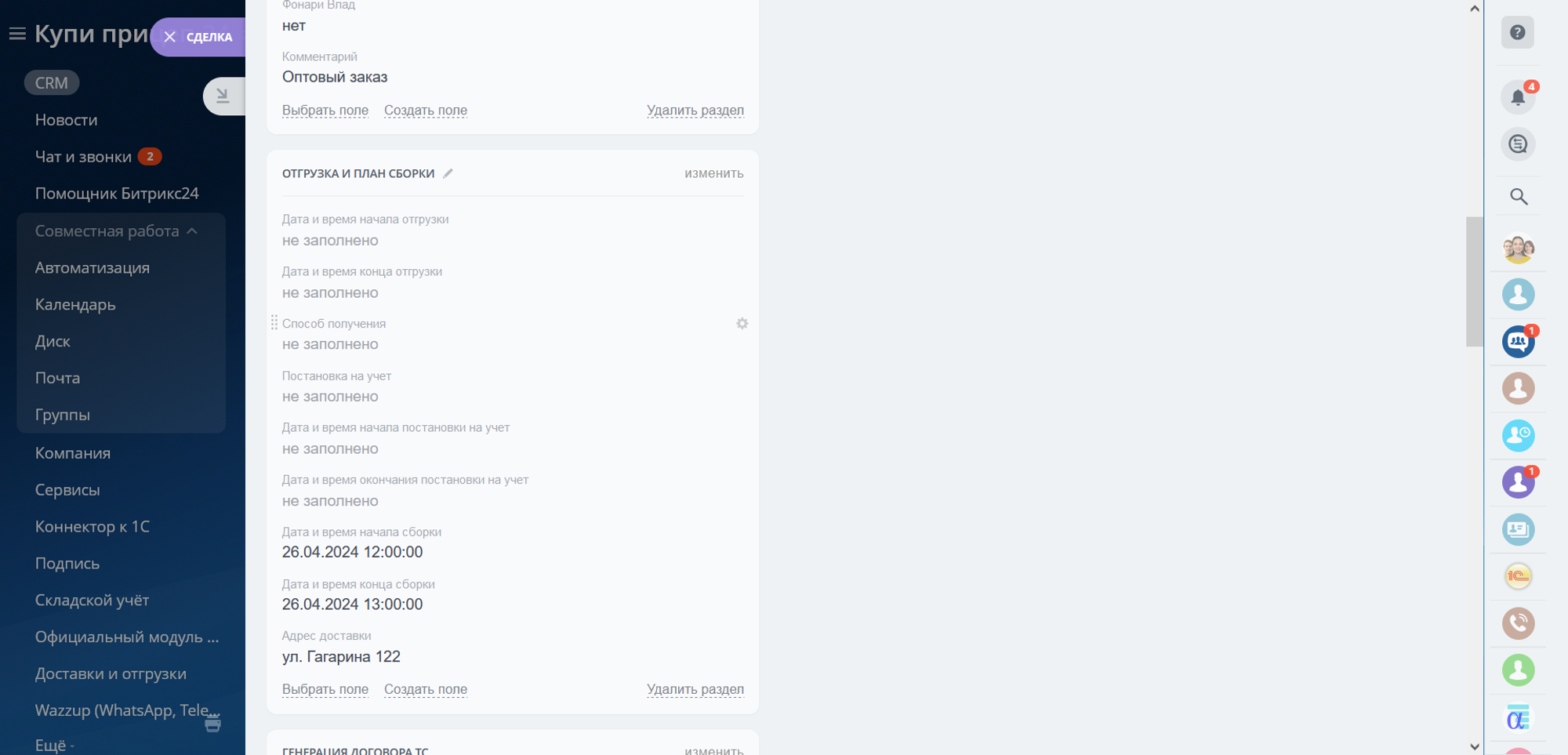

- Two cases are created in the deal card. It’s one thing for an assembly employee in a warehouse. The second is for logistics. Moreover, the date and time of order assembly depend on the date and time of order delivery.

The warehouse employee who collects the order has access to information only with the contents of the order, and the amount and address are not displayed.

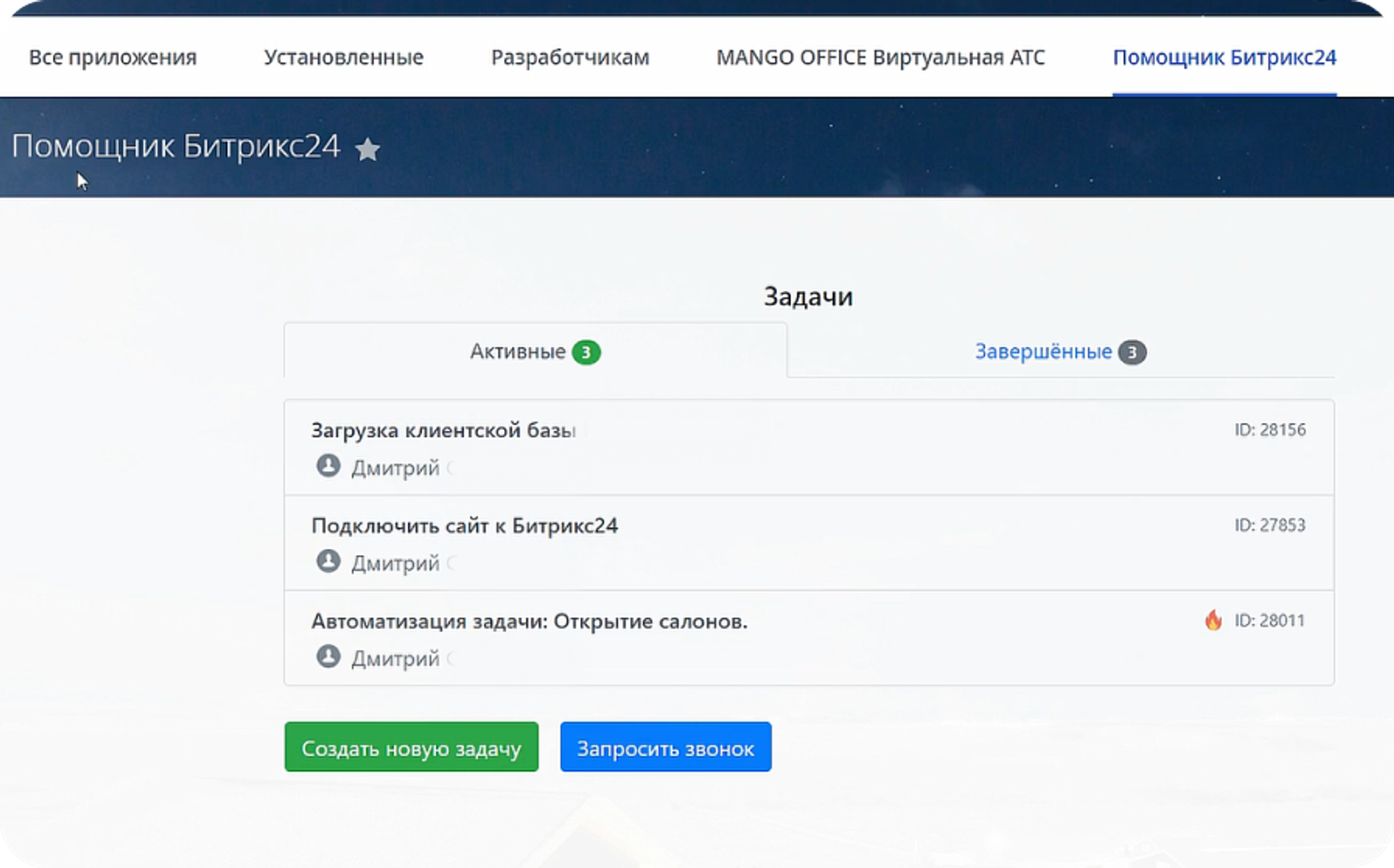

How employees see it

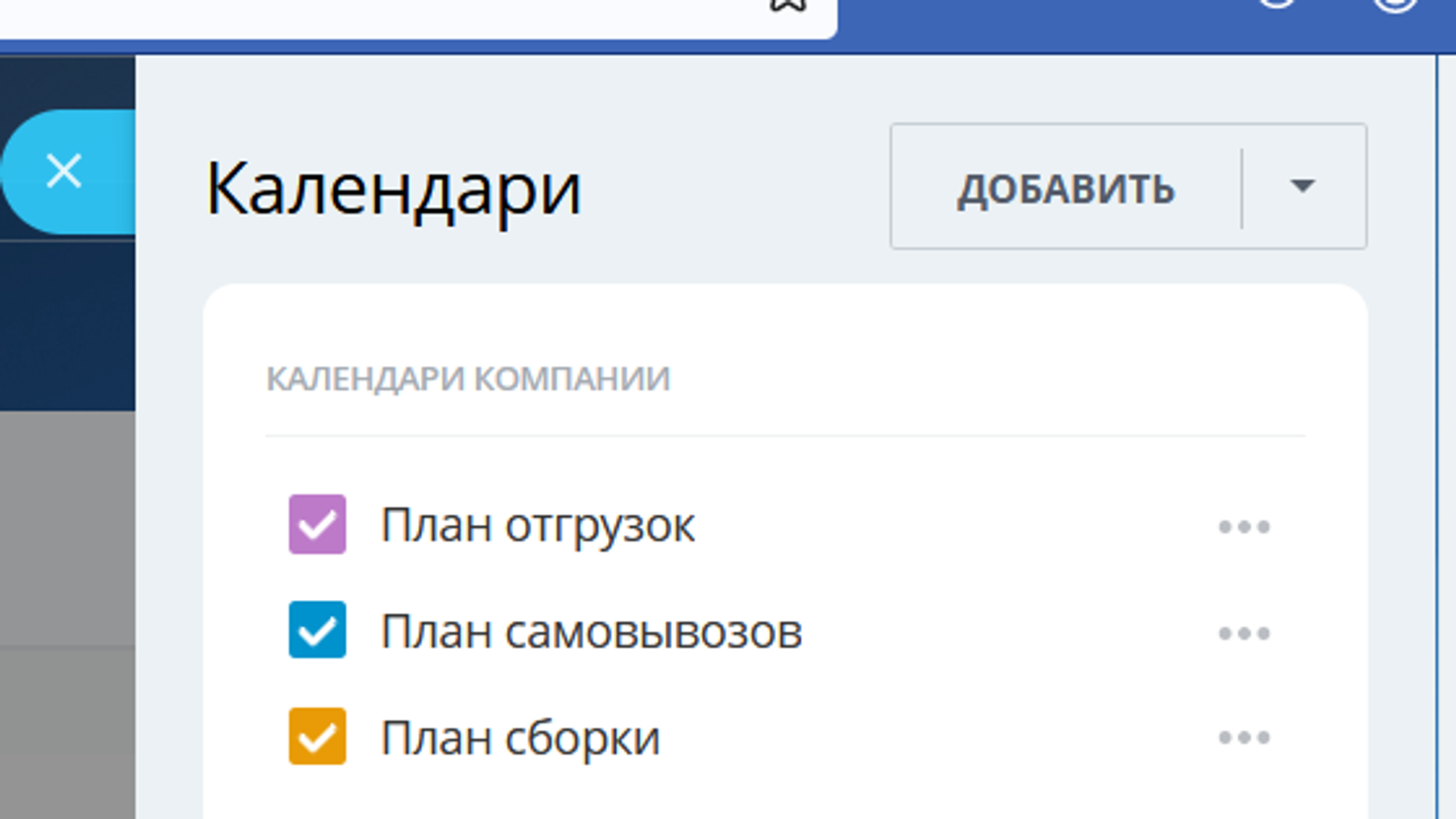

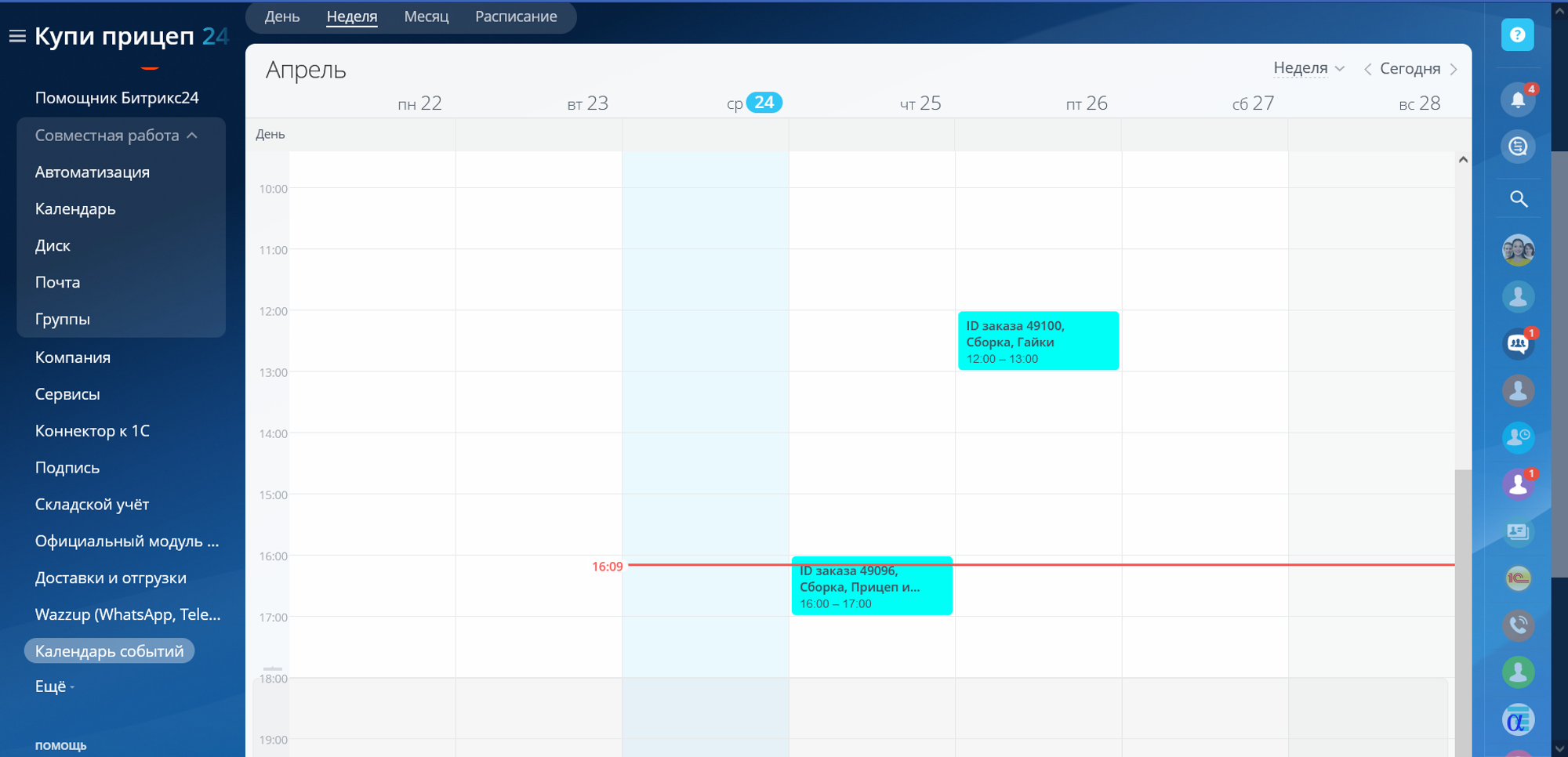

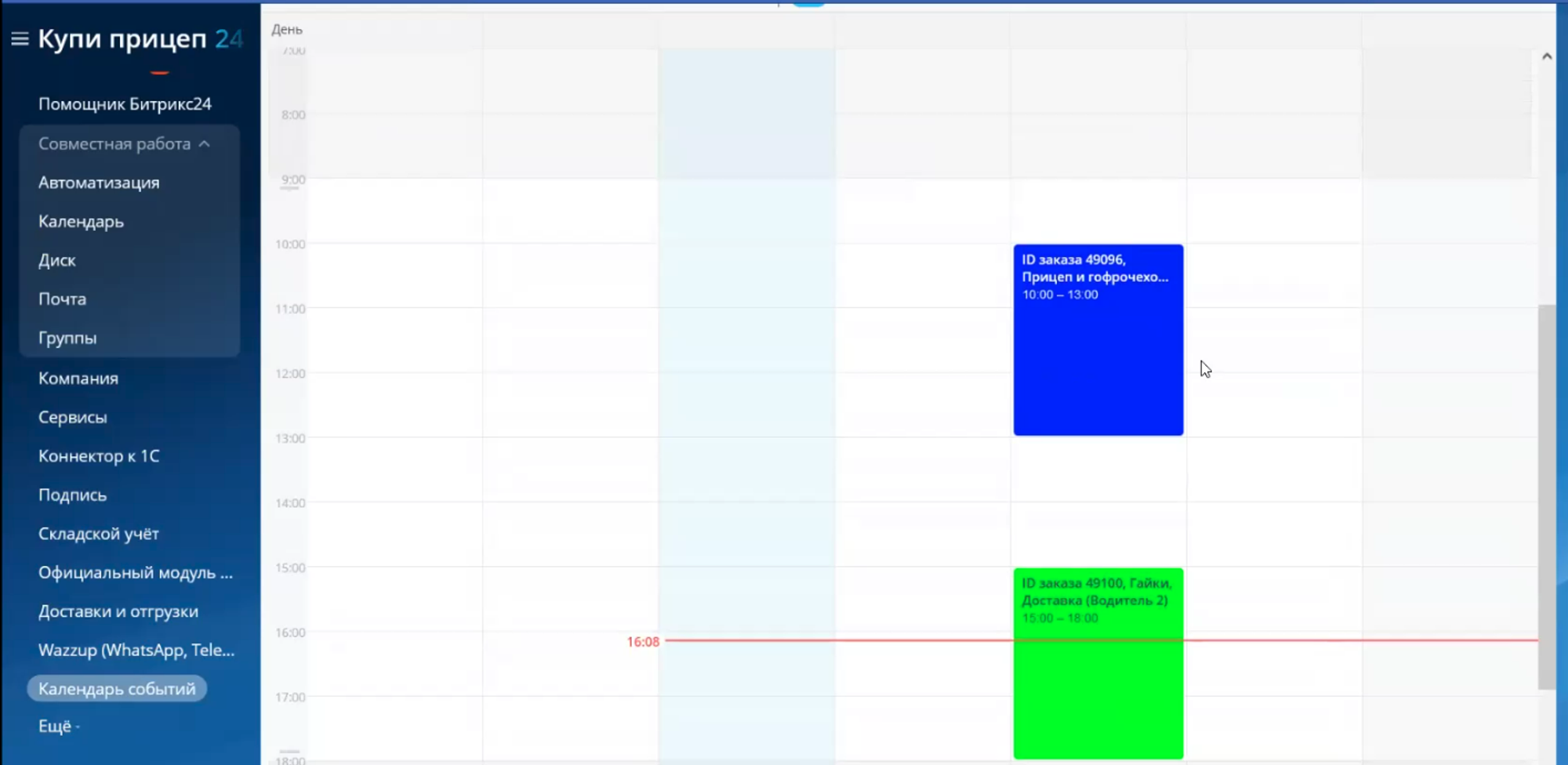

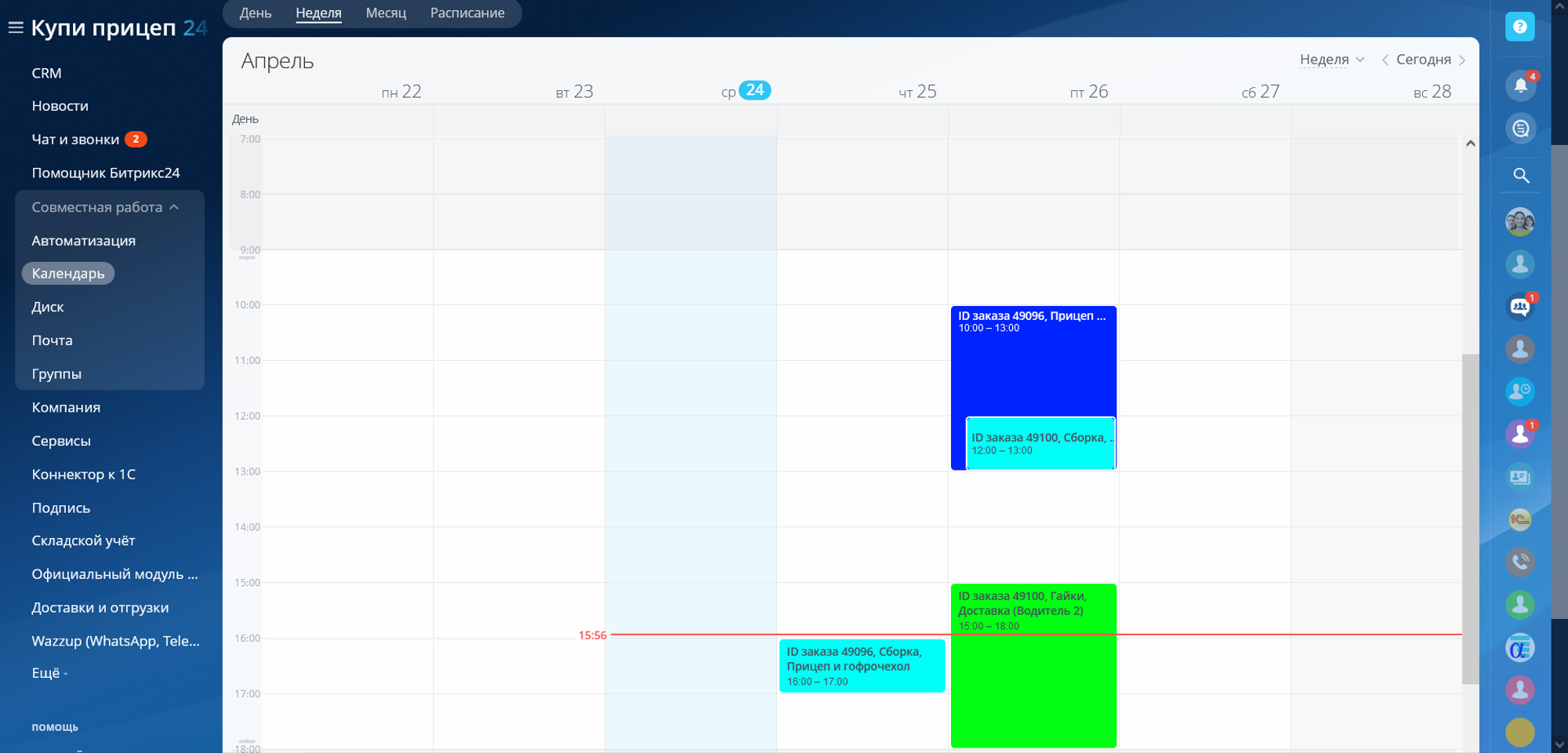

On the calendar

The company's main calendar implements three different schedules: an assembly plan, a shipping plan, and a pickup plan. The manager has access to all of them to see the load and control the processes.

Pickers and drivers only see calendars that directly apply to their departments.

The calendar displays the event for delivery at the specified time, as well as the assembly event the day before. The logic has been implemented according to which the date and time of assembly depends on the date and time of delivery/pickup. For example, if delivery is made between 9 am and 12 pm, then the order is assembled the day before from 4 pm to 5 pm.

Different colors of calendar events are used for different delivery drivers and pickup stores for a better visual perception.

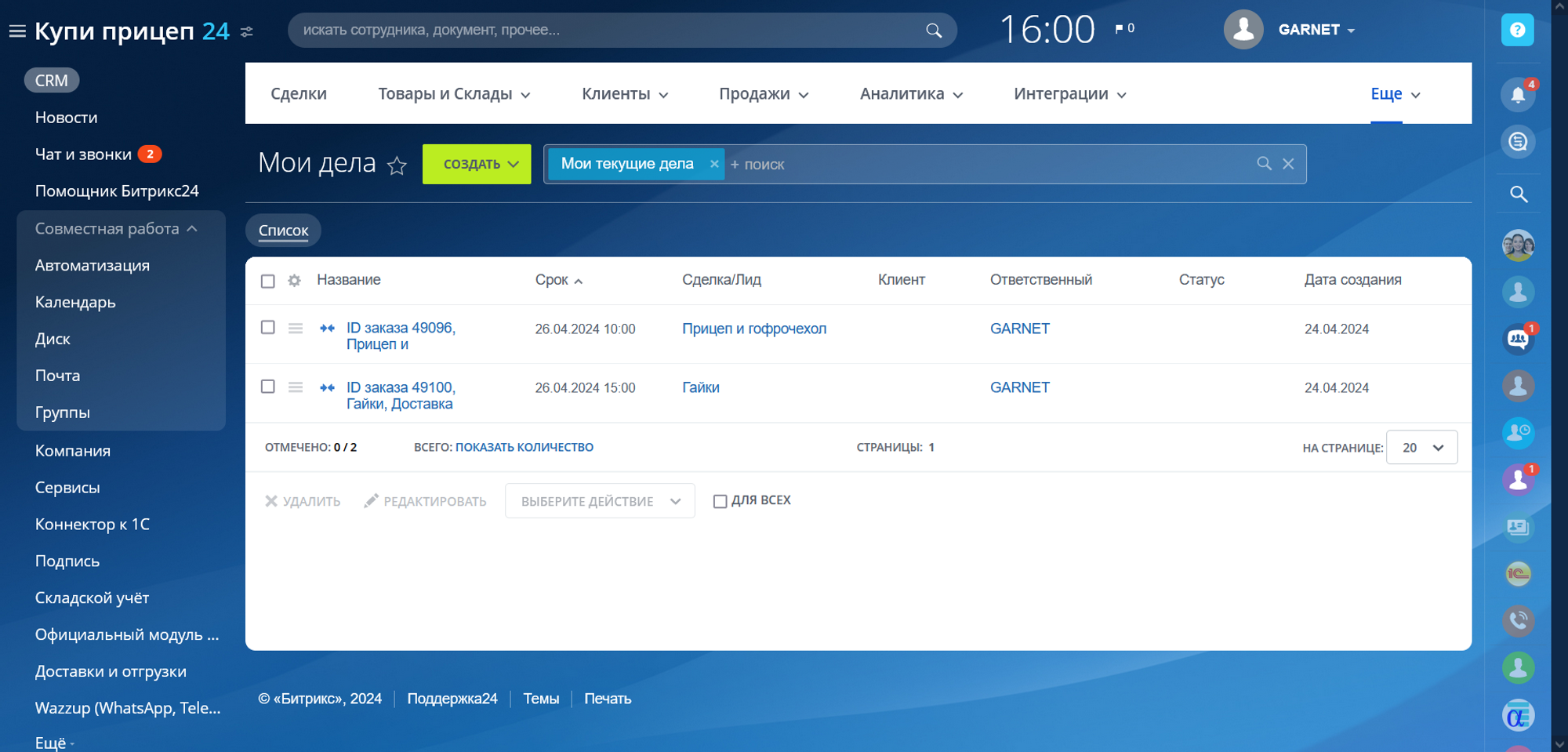

В CRM

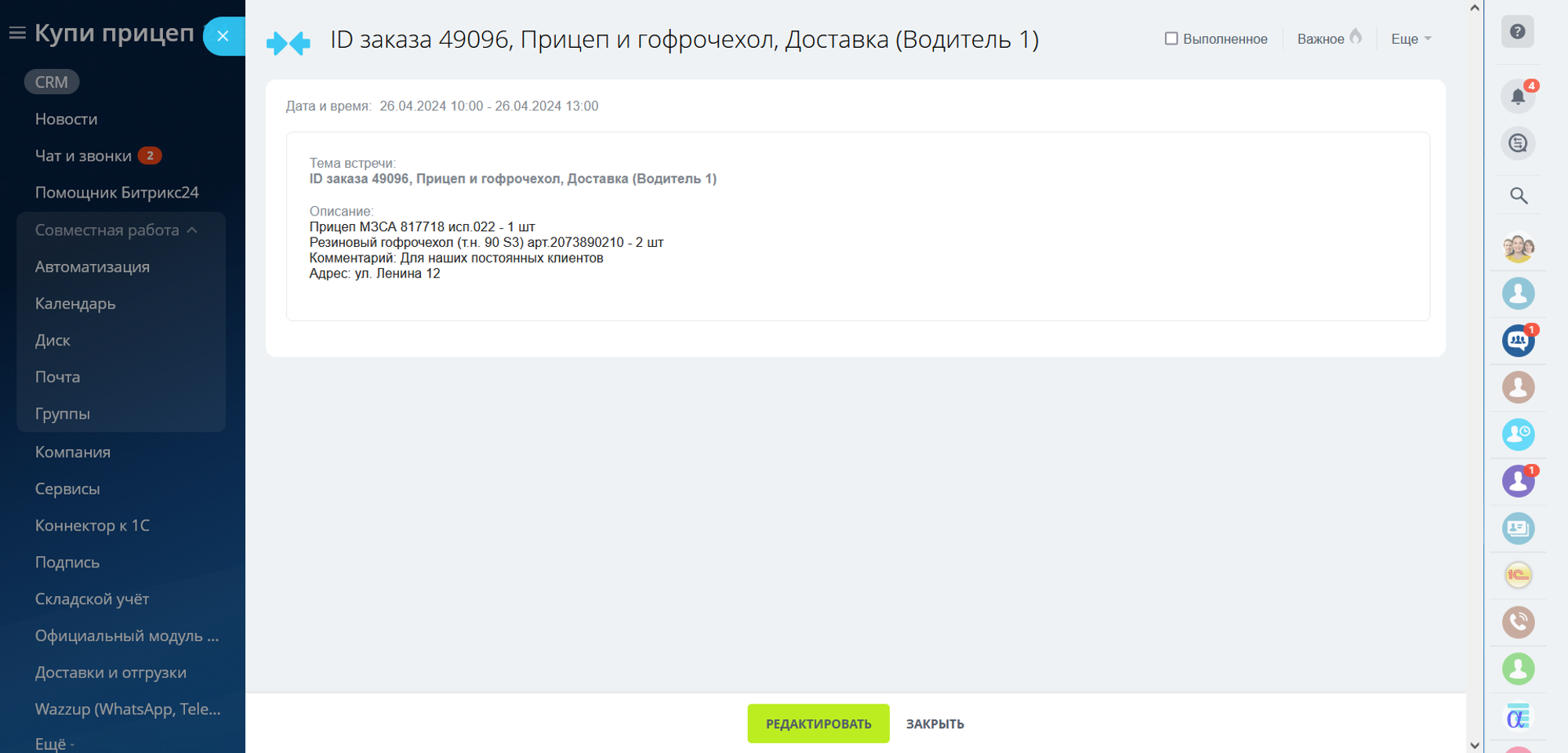

In the My To Do section, the employee sees a list of his to-dos for the current day, which are ordered by time.

For example, this is how the driver sees deliveries for today.

Each delivery contains all the necessary information about the order: composition, comment, address (you can customize any logic and display additional information)

Data protection

In case the order date/time/delivery address has changed, only the manager can make changes.

In this particular example, logic is configured where the manager moves the deal to a certain stage and automatically deletes all information in the corresponding fields.

After this, the manager enters up-to-date information on the order and sends it for assembly.

Warehouse employees, assemblers, and drivers do not have access to edit or make additions to the order.

Advantages

- This schedule ensures that orders are completed on time.

- The manager can plan and distribute the load of drivers, thereby not overloading any one person.

- It's easy to arrange delivery for different customers if their delivery times are the same. This avoids delays or rescheduling.

- Limiting order editing protects against possible errors or inaccuracies.

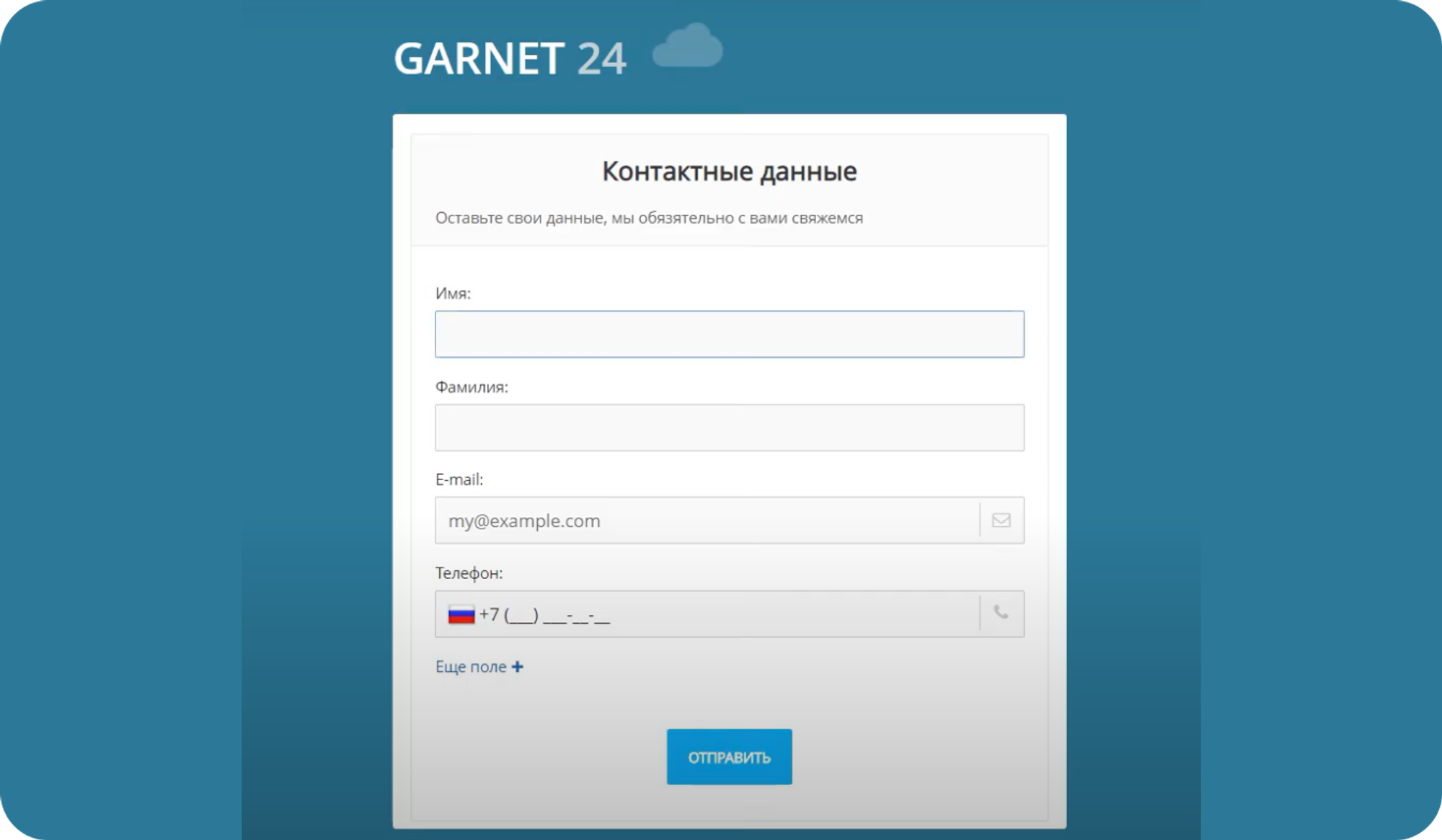

Have questions or need to find a solution to Your problem?

Leave a request by filling out the feedback form. Our expert will contact you as soon as possible